Features:

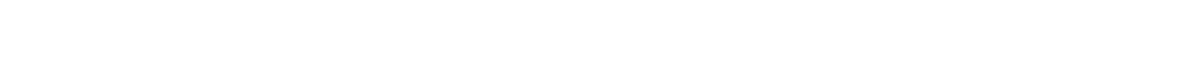

In industrial electric heating application system, there are three methods to adjust electric heating power

1. Phase shift voltage regulation control;

2. Duty cycle control;

3. Cycle power regulation control;

Cycle power regulation control overcomes the shortcomings of high harmonic interference caused by phase-shift voltage regulation, and the power output stability is far better than the duty cycle control mode, which improves the regulation accuracy and saves electricity obviously.

Applications:

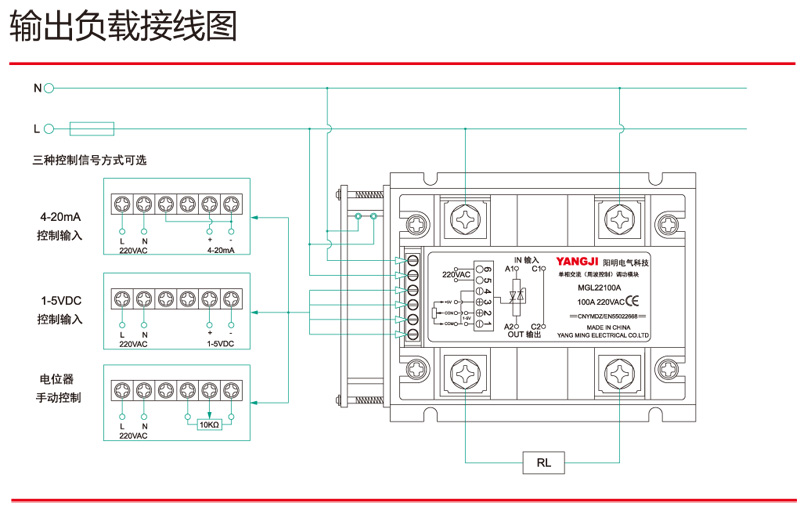

The module adopts SMT technology of imported components, accepts 1-5V, 4-20mA signal input, or 10K potentiometer direct manual control, generates the corresponding cycle zero crossing control signal output, drives the load, has small impact on the load, strong anti-interference and high reliability.

It is used for temperature control of lighting equipment, oven and other heating equipment.

1. The selection of module current specification should take into account the fluctuation of grid voltage and instantaneous current impact when load starts, environmental conditions and heat dissipation conditions, in order to ensure the long-term reliable operation of the module, it is suggested that:

Resistive load: the current capacity of the selection module is 3-4 times of the actual working current;

Inductive load: the nominal current of the module should be 5-6 times of the actual current of the load;

2. The module can't output large current for a long time (high input voltage, low output voltage). It may cause the module to burn out. It is suggested that the output voltage of the module should be adjusted above 1 / 2 of the input voltage.

3. Over voltage and over-current protection: the output terminal of the module is connected in parallel with a varistor (voltage 800-900v), which can effectively protect the over-voltage. The main circuit is connected in series with a quick fuse or a circuit breaker as the over-current protection, and the &#118alue is 1.5 times of the actual current.

4. The working calorific &#118alue of the module is calculated according to the actual current * 1.5; The radiator must be installed above 10A, forced air cooling or water cooling above 40A, to facilitate the effective heat dissipation of the module, to prevent the module from burning electronic components or chip breakdown due to high temperature.

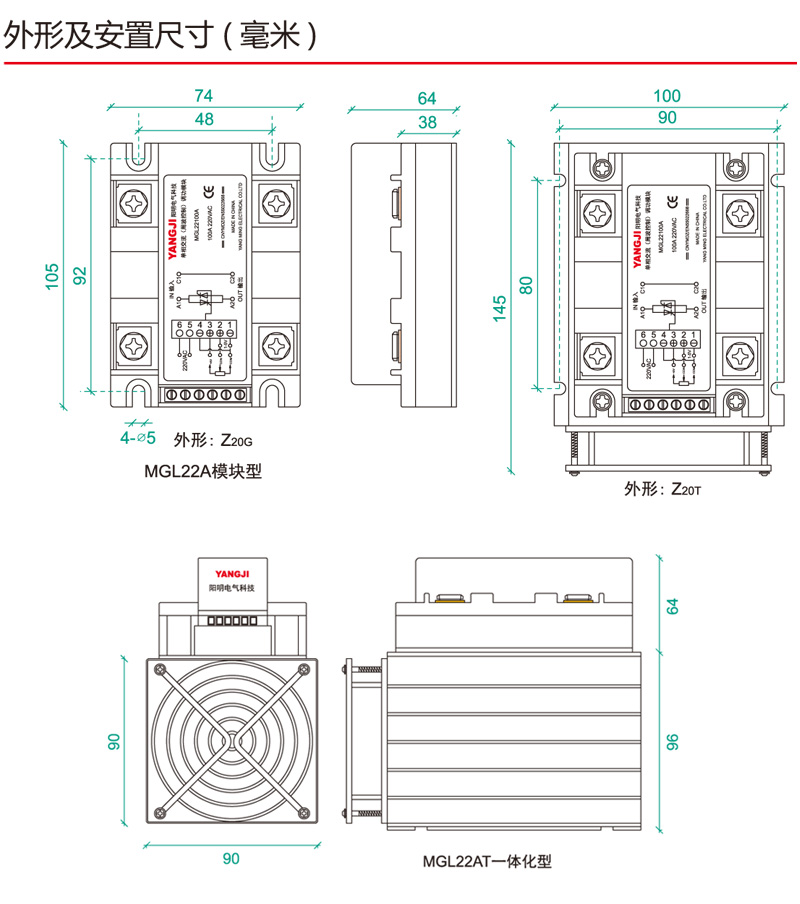

Code: Z20G

|